The Metal Sheets and Metal Plates sound the same right! But they are different products and producing them for different purposes. When you know the exact difference between metal sheets & metal plates, you can use the product well-suited place and also customize them.

What Are Metal Sheets?

Sheet metal is metal that is thicker than foil and thinner than 6mm. Metals Sheets are one of the fundamental forms. It is used in metalworking like shaping and reshaping the metals to create objects, assemble, etc,…

Metal sheets are in the form of foils or sheets and pieces. The sheet metal which is thicker than 6mm is considered ‘structural steel’ or ‘plate steel’. The main purpose of using metal sheets in construction is to create structures without adding extra weight. This is less in durability.

What Are Metal Plates?

Any sheets that are thicker than more than 5mm are called Metal Sheets. Metals Plates are used where durability is highly needed.

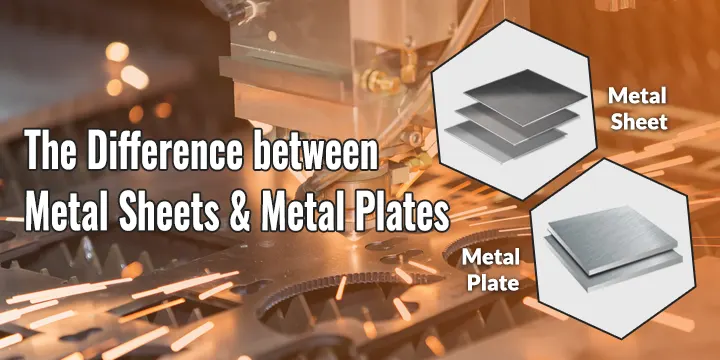

The Difference between Metal Sheets & Metal Plates?

Sheet and plates are different categories of names to distinguish the metals for various uses. The only difference between Metal Sheets & Metal Plates is thickness. The thickness is the only deciding parameter whether the plates are needy or sheet is.

Most metals are cast into billets and slabs. Billets are mostly used in the form the bars and wire. Slabs are the only things that are used to form sheets and plates. To make usable sheets or plates, the metals are rolled either hot or cooled by the hot rolling or colled rolling process.

Hot rolling is the metalworking process where the metals are heated above recrystallization temperature. This process is used to create or reshape the desired object. Hot rolling improves Toughness, Ductility, and Weldability.

Cold rolling is a process used to change the material properties of metal. Cold rolling improves dimensional accuracy, straightness, hardness, yield strength, tensile strength, and surface finish.

Usage of Metal Sheets

Though it is versatile are mostly use in constructions and more fields they are

- Hospitality,

- Farming,

- Manufacturing,

- Mining,

- Shipping,

- Catering,

- Aviation,

- Medical, and

- Transport.

Usage of Metal Plates

Metal Plates are used in more processes like

- Structural members,

- Bridges,

- Storage tanks,

- High-rise buildings,

- General fabrication, and

- Mixers.

There are types of sheets and plates. They are

Hope you know the difference between Metal Sheets & Metal Plates and their significant purpose. Contact the best steel dealers in Chennai to know more about gauges and grades of metals.

Leave a Reply